Home » Posts tagged 'services'

Tag Archives: services

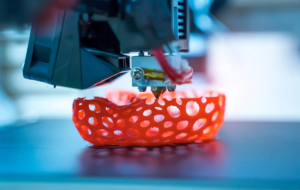

The Benefits of 3D Printing

3D printing involves the production of three-dimensional objects from digital models, which are mathematical representations of a part or product. These are then printed using one of many different technologies, such as sintering or stereolithography.

The main business applications for 3D printing include prototyping and creating tooling aids like injection moulds and jigs. With reduced lead times, businesses can produce multiple design iterations in a fraction of the time. Contact By3Design now!

The rapid prototyping process allows for a more user-centric approach to product development, with designers gathering feedback through testing and refining their designs to meet users’ needs. This iterative design cycle helps to reduce cost and time to market, ensuring the final product will perform as intended.

In addition, the physical nature of a prototype allows companies to identify and resolve design flaws before production starts. This ensures that the finished product will be both functional and attractive.

There are a variety of ways to create a prototype, depending on the specific project requirements. For example, low-fidelity prototypes are basic representations of the final product without any detailed functionality, used in early stages to test concepts and gather user feedback. High-fidelity prototypes are more accurate and close to the final product, often used for visual testing.

3D printing is a popular method for rapid prototyping because it offers a wide range of benefits. It improves communication through visual representations, identifies problems with the design process quickly and efficiently, and provides the opportunity for continuous testing to identify user needs. This iterative process saves time and money, while also reducing risk and enhancing the quality of the final product.

While there are many different 3D printing processes, the most commonly used is fused deposition modelling (FDM), found in most non-industrial desktop 3D printers. A spool of thermoplastic filament is melted and deposited onto a surface layer by layer to build the model. FDM is suitable for most applications, although it is best suited to lightweight and durable parts.

Another widely-used technique is stereolithography (SLA), which uses a laser to solidify a 3D printed model-also in a layer-by-layer process-from a vat of liquid resin. SLA is ideal for complex and large scale models, as well as parts with intricate details.

When creating a prototype, it is important to clearly define the desired test objectives from the start. This will help to avoid wasting time and money on unsuitable materials and techniques. Also, it is essential to include stakeholders in the design and testing process. This will enable all parties to identify and address potential issues in the early stages of development, reducing the chances of costly errors in the future.

Customised Parts

A key benefit of 3D printing is the ability to create customised parts. This is particularly useful for industries that rely on stringent performance standards. For example, automotive manufacturers can use 3D printing to create rugged housings for sensitive components that boast resistances to heat and water. 3D printing is also an excellent tool for reducing product costs and inventory by manufacturing spare parts on demand. This reduces lead times and allows manufacturers to work with reduced stock levels while providing customers with prompt service.

The ability to rapidly produce prototypes is also useful for iterating a design before moving into production. This can be much faster than traditional methods that require the creation of new moulds or tooling. As a result, a single design iteration can be tested in a range of applications to ensure that it is fully functional and fit for purpose. This is especially helpful for high-tech products where small improvements can make a big difference to a final product’s functionality, comfort, aesthetics or efficiency.

Consumer goods companies can also leverage 3D printing to offer personalised products. This is a great way to assert a brand’s creativity and individuality, as well as responding to consumers’ needs and desires. For example, some designers have created ‘print-at-home’ garments that allow customers to print and wear bespoke fashion pieces. The ability to produce a customised part for every customer can also help businesses build loyalty and brand trust.

In healthcare, medical professionals can also leverage the power of 3D printing to produce customised implants and prosthetics for their patients. This is a growing area of the industry that uses digital workflows, such as GrabCAD software available from SYS Systems, to convert imagery from CT and MRI scans into precise 3D models. Then, medical professionals can print custom-made implants and surgical guides to fit perfectly into each patient’s unique anatomy.

Aside from accelerating industrial product development, the speed at which 3D printers operate is also crucial for streamlining supply chain processes. This allows manufacturers to quickly respond to market demands, increase production yields and minimise machine downtimes.

Faster Time-to-Market

The speed of 3D printing allows for design changes that might take months with traditional manufacturing to be implemented in a matter of days. This means companies can quickly iterate and perfect their designs to bring products to market faster. This is particularly useful in the automotive industry, where car manufacturers can quickly print spare parts to keep their production lines running as quickly as possible during breakdowns or for a quick replacement when something breaks.

To produce a 3D printed part, a virtual design must first be made using computer-aided design (CAD) software. This creates precise drawings and technical illustrations of the object, much like a blueprint for how to make it. Then, the CAD file is prepared for 3D printing by breaking down the model into many layers. The process is known as slicing, and it prepares the virtual design for printing by taking it apart into hundreds or thousands of thin horizontal layers. Each layer is then printed with a special plastic or metal material. The final product can then be used as intended.

For example, jewellery designers often use 3D printers to print prototypes and to test the fit of a piece. This allows them to experiment with different shapes and aesthetic finishes, sidestepping some of the limitations of conventional jewelry making techniques such as CNC machining or lost-wax casting. This flexibility also lets designers experiment with new and innovative designs that might not be viable with other methods.

Increasingly, industrial goods manufacturers are using 3D printing as an end-use production technology. This is due to the fact that it can produce a large variety of parts without requiring a complex manufacturing setup or expensive injection molds. It also enables them to produce parts on-demand, reducing the need for costly inventories and enabling supply chain agility.

This capability is already being utilized by aerospace and defence industries to print high-value components in-house, reducing time-to-market for new aircraft or weapons systems. It’s important to note, however, that there are still a few hurdles to overcome before this type of manufacturing can become mainstream, such as ensuring that additively produced parts meet stringent industry standards and have the durability required for end-use.

Reduced Waste

3D printing is a highly efficient process, using the exact amount of material needed to create a part. This greatly reduces waste compared to traditional manufacturing techniques, which typically require large amounts of excess material for assembly and support.

The elimination of waste also helps to conserve natural resources and prevent pollution. Many traditional manufacturing processes rely on sourcing materials from long distances and transporting them for on-site processing, resulting in substantial carbon emissions. By eliminating the need for this transportation, 3D printing significantly cuts greenhouse gas emissions.

Additionally, the use of recycled materials in 3D printing can further reduce the impact on the environment. These materials are derived from a variety of sources, including repurposed filaments and scrap plastics from other 3D prints. Using these materials also helps to reduce the demand for new materials, further decreasing waste.

In addition, a variety of advanced software and design algorithms can be used to optimize the use of material in 3D printing. These strategies, known as topology optimization, help to make structures stronger and lighter, reducing overall material consumption while improving durability. This can lead to a reduction in maintenance costs over time, further reducing the environmental impact of the technology.

By enabling businesses to confirm a design before making the investment of creating physical prototypes, 3D printing reduces the risk of errors and wasted materials. This is a significant advantage over traditional manufacturing methods, where errors can be costly and time-consuming to correct.

With the flexibility offered by 3D printing, companies can manufacture products on-demand and only as they are needed. This can significantly reduce the need for inventory storage, which requires costly space and energy. It can also ensure that parts are made only when the product they are designed for is required, removing waste associated with obsolete or surplus inventory.

In addition, on-demand manufacturing can also reduce the need to import materials from overseas, which can result in a decrease in foreign trade and environmental footprint. Finally, the ability to produce parts locally can reduce the need for long-distance transportation and cut fuel usage, further reducing the impact of 3D printing on the environment.

Preventive and Corrective Pest Control

Clutter provides places for pests to breed and hide. Keep rubbish bins closed and empty, remove rotting logs from the garden, clean birdbaths regularly, and drain puddles that might harbor mosquitoes.

Monitoring pest numbers is essential. Accurate identification helps you decide on the best control tactics. For example, some pesticides may harm native animals, so avoid spraying near wildlife. Click https://facilitypestcontrol.com/ to learn more.

The best and least expensive way to manage pest problems is to prevent them from occurring in the first place. This involves understanding and evaluating the conditions that allow a pest to flourish, such as conducive habitat or food supply, and making changes to reduce those conditions. Preventive programs also include a thorough inspection of both the exterior and interior of a facility to identify entry points and attractants, then taking steps to close them.

For example, in a home, sealing gaps in doors and windows, securing venting systems, and keeping trash cans tightly sealed are preventive measures that can deter pests from entering the building. Similarly, in a plant, removing waste materials, maintaining landscaping and draining wet areas can keep pests away from the facility.

Whether in homes or industrial facilities, prevention is the preferred method of pest control. But for a variety of reasons, it may not always be feasible or practical to completely avoid pests. In these cases, pest control goals shift from prevention to suppression and, eventually, eradication.

Eradication is rarely attempted in outdoor pest situations because of the difficulty of totally eliminating a population. However, eradication is often the goal in enclosed environments where a pest can cause significant harm. For example, a pest infestation of a health care or food-processing facility might be considered unacceptable and require eradication efforts.

Natural forces that affect pest populations include climate, natural enemies, natural barriers such as mountains or waterways, and available shelter, food and water supplies. Some pests thrive only as long as their food or roost is available, while others need to overwinter or hide from predators.

In the absence of preventive methods, pests can be controlled using a number of mechanical and physical techniques. Some of these techniques involve modifying the pest’s environment, such as trapping and dispersing it with an attractive bait or changing the climate around it. Other techniques include physical controls such as traps, screens, barriers, and fences; radiation and electricity; and the use of heat, cold, and sound. These methods can be effective in controlling some pests, particularly insects, but may not be suitable or desirable in all situations.

Suppression

Preventive measures are economical and environmentally responsible methods that reduce conditions favorable to pests. They include mowing, pruning, weeding, crop rotation, plant sanitation, soil management, cleaning greenhouse and tillage equipment and scouting (regular searching for, identifying and assessing numbers of pests and their damage).

Suppression focuses on slowing or stopping the growth of pest populations to levels acceptable to humans and the environment. This can be done by a variety of chemical, biological and cultural controls. In horticulture, many pest control problems are controlled with plant growth regulators that slow or stop plant growth and/or prevent reproduction. In agriculture, plowing, cropping and proper use of manure can disrupt the habitats where pests live and allow other organisms to fill the void.

Biological controls are living organisms that attack or parasitize pests, making them less damaging than they would be otherwise. These organisms are called natural enemies, and they arc very important in keeping pest densities low. Examples of natural enemies that can be used to suppress pests include predators, herbivores, pathogens and competitors. Increasing the number of natural enemies of potential pest insects is accomplished by conservation of existing ones, mass rearing and release of the enemies on a regular basis, or introducing them from other locations.

Chemical controls are substances, usually chemicals, that are applied to kill or inhibit pests or their growth. These substances, sometimes referred to as pesticides, come in a wide range of forms and are classified according to their intended use. Examples of pesticides include herbicides, insecticides, fungicides and rodenticides. Most pesticides are regulated by federal, state and local authorities to ensure that they are safe for their intended uses and do not harm people or the environment.

Some pests have a zero tolerance threshold and cannot be present in certain environments because of the severe human health, environmental or economic damage they will cause. Eradication, therefore, is a common goal in indoor pest situations, such as those found in homes; schools; office buildings; and health care, food processing and food preparation establishments. However, eradication is much more difficult in outdoor pest situations such as citrus groves.

Eradication

Once pests have been identified and their habits are understood, they can be controlled using preventive or corrective measures. This may include removing the food and shelter they need, such as removing debris or sealing trash containers. Preventive measures are often easy to implement and can reduce the need for chemical pest control methods, which often contain toxins that pose health or environmental risks upon exposure.

Physical traps, netting and decoys are examples of preventive measures that can be used in conjunction with other pest control strategies. They are designed to keep pests away by blocking access to a desirable area. Physical traps usually require human intervention to set and remove a caught pest, so they are not as effective as other pest control methods.

Pesticides are solutions that contain poisons and can kill pests, usually by targeting their nervous system. They can be sprayed directly on a pest or in a bait that lures them to their death. Most pesticides are toxic, so only certified and licensed pest control technicians should have access to them. They should be used only when absolutely necessary and never on children or pets, which can be affected by even small amounts of pesticides.

Chemical pest control is often quick and can produce results immediately. It can also be more expensive than other options. It can also lead to an imbalance in the ecosystem if overused. Many pests have complex life cycles and can develop resistance to chemicals, making them a challenge for even the most skilled pest control professionals to eliminate completely.

The amount of time the extermination process takes depends on how well you prepare for it beforehand, such as removing clutter or keeping animals out of the way. It also depends on the size of your home and the extent of your pest problem. An initial inspection and a customized treatment plan can take from 30 minutes to a couple of hours. Once the treatment is done, you can usually expect a follow-up visit, depending on your pest problem and whether it needs to be corrected.

Monitoring

Pests cause damage to property and can also spread disease. They can be difficult to eliminate, and it is important to monitor pest infestations so that they do not get out of control. Pest control professionals can help businesses to identify the type and extent of a pest infestation, develop a customized plan to control the pests, and implement the plan. They can also provide ongoing monitoring and maintenance to prevent pests from returning.

Monitoring is the process of checking or scouting for pests to determine what kinds are present, how many there are, and what kind of damage they are doing. This can be done visually or with traps, pheromone strips, sticky traps, or bait stations. This information is used to develop a threshold, which is the number of pests at which action must be taken to reduce their numbers and prevent unacceptable damage or injury. Monitoring can be used to monitor insect, insect-like, mollusk, vertebrate, and weed pests. It can also be used to monitor plant diseases and fungus.

The monitoring process can be complicated and involves several factors, including the ability to accurately identify the pest, its life cycle, the environment in which it is living, and its preferred food sources. Pest control professionals use this information to determine the best method for controlling the pest, and they may consult with experts in the specific pest, such as a university or government extension agent.

Sometimes a pesticide application will fail to control the pests. This can be due to resistance, choosing the wrong pesticide, misidentifying the pest, applying the pesticide at the incorrect time or place, or simply because the environment is not changing sufficiently to suppress the pest population.

Keeping pests out of commercial premises is essential to maintain business operations and comply with health, safety and hygiene regulations. Using pest control services that have the proper certifications and expertise can ensure that all pests are removed quickly and effectively.

Insects such as cockroaches and flies can spread diseases, while rodents like mice and rats can chew through wires and create fire hazards. They can also leave droppings and smear marks, which can spoil food, and transmit pathogens such as leptospirosis, Salmonella, and lymphocytic choriomeningitis (LCMV). Having the right pest control strategies in place helps to keep these vermin away from commercial premises and protects the health and wellbeing of customers and employees.

Productized Profits Review

Many people may be skeptical about Productized Profits Review because of the success stories that Lucas Lee Tyson uses on his sales page. But, the truth is that these success stories do not represent the average results.

This program is a digital marketing training course from Growth Cave, and it teaches you how to run leads via Facebook ads. It also includes 1-on-1 coaching and Q&A calls.

Productized Profits is a digital marketing course that teaches you how to launch and run a successful agency. Lucas Lee Tyson, the founder and CEO of Growth Cave, an online digital marketing academy, authored the course. The program will help you build a profitable digital marketing agency that can generate high-paying leads and clients.

The course is divided into seven weeks and includes video lessons, live Q&A sessions, and other resources. It covers the entire process of starting and running a local lead generation business. You will also learn how to create a website, use social media for business, and get your first client. This course is ideal for beginners in the field of local marketing.

The course costs $1497 upfront or three “easy” payments of $597. A 30-day action-based refund policy backs it. This means that you must show that you have attempted to implement the techniques in the course before you can get your money back. This is a better refund policy than many other programs offer.

However, the program does have some drawbacks. First, it relies on software to find clients, which can be risky. If the software fails for a week, you cannot land new clients. You must be aware of this major problem before purchasing the program.

You will also be required to invest in the program’s software, which can cost up to $99 per month. This can be expensive and may make the program unaffordable for some people. In addition, the training offered by the program is less comprehensive than you might expect. Other online courses cover more aspects of digital marketing.

Productized Profits is a great digital marketing course for beginners who want to start their local marketing agency. However, if you want a more complete course to teach you how to build a full-fledged digital marketing agency, you should consider other options.

The Productized Profits course will teach you how to package your services into “products” that can be sold to clients for a fixed fee. This is something that many digital marketers do to maximize their profits and minimize the amount of time they spend working on each project. It also allows them to scale their agency by outsourcing some work to freelancers. This is a great way to make money online, especially for people with limited time and budgets.

The Productized Profits course will teach you various lead-generation strategies, including cold emailing and Facebook ads. These are all things that have been proven to work, so you can feel confident that the Productized Profits course will give you real-world results.

A 30-day action-based refund policy also backs the program. This means you can get your money back within 30 days if you can prove that you’ve done everything possible to achieve results but have yet to succeed. This is a much better refund policy than what you’ll find with other online courses and programs, which often have hidden fees or loopholes that make it impossible to qualify for a refund.

In addition to the course materials, you will also receive access to a private Facebook group where you can ask questions and receive support from other members of the Productized Profits community. This is a great way to stay motivated and keep your spirits high during the tough times, which can happen at any point in building your online business.

Productized Profits is a digital marketing training program created by Lucas Lee Tyson and his company, Growth Cave. It is designed to teach people how to start a lead generation agency and grow it into a six-figure business. Its curriculum is broken down into seven modules and includes:

- Lessons on creating irresistible offers.

- Setting up a client magnet machine.

- Mastering sales.

- Automating systems.

The program also covers the importance of building relationships with potential clients and how to close them.

Productized Profits is an online digital marketing training program that teaches you how to start and grow a successful agency in less than one month. It is a part of the Growth Cave program that Lucas Lee Tyson created, and it has everything you need to make passive income from your digital marketing agency. It includes six modules, the ClientBolt software, 1-on-1 coaching, and Q&A calls. It is not cheap, but it’s worth it if you can afford it and are committed to making it work.

The program offers a variety of training modules that teach you how to set up your business, get your first client, and scale up. It also teaches you how to package your services and attract high-paying clients. You’ll also learn how to run Facebook ads, which are essential for generating leads and getting new clients. The course is based on the principles of a client-first agency model. This means you will focus on meeting your client’s needs and providing excellent service. The course also emphasizes the importance of automating as many tasks as possible so that you can spend more time on building your agency.

Although the program is a great training tool, there are some drawbacks. First, it focuses on a single platform for lead generation. While this is a good idea in the short term, it could be more sustainable in the long term. Facebook is becoming oversaturated, and standing out from the crowd is hard. This program would be much better if it taught other strategies for generating leads, such as YouTube videos and email marketing.

Another drawback of the program is its refund policy. While the Productized Profits sales page clearly states that the program is not a scam, some hidden requirements could prevent you from getting your money back. For example, you must be a member of the Productized Profits community and attend at least two of the weekly Q&A calls to qualify for a refund. This is a shame, as it could deter people from investing in the program.

Productized Profits is a comprehensive local marketing agency system designed for beginners. It includes step-by-step guides, pre-built templates, and access to a supportive community. However, this program is only for some and requires high dedication and hard work to see results.

The program teaches students to package digital marketing services in a niche and run Facebook ads to generate client leads. The course also covers client acquisition strategies and building a profitable service business. In addition, students get access to sample strategy phone calls with Lucas Lee Tyson to learn how to close client deals.

Lucas Lee Tyson started Growth Cave in his college dorm room with less than $50 to his name. He has since grown his company into a six-figure earner and is one of the top providers of Facebook and YouTube advertising training. He aims to help people become financially independent by running digital marketing agencies.