Home » Printing Services

Category Archives: Printing Services

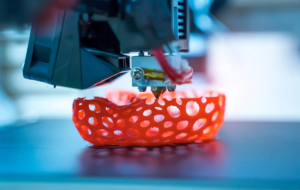

The Benefits of 3D Printing

3D printing involves the production of three-dimensional objects from digital models, which are mathematical representations of a part or product. These are then printed using one of many different technologies, such as sintering or stereolithography.

The main business applications for 3D printing include prototyping and creating tooling aids like injection moulds and jigs. With reduced lead times, businesses can produce multiple design iterations in a fraction of the time. Contact By3Design now!

The rapid prototyping process allows for a more user-centric approach to product development, with designers gathering feedback through testing and refining their designs to meet users’ needs. This iterative design cycle helps to reduce cost and time to market, ensuring the final product will perform as intended.

In addition, the physical nature of a prototype allows companies to identify and resolve design flaws before production starts. This ensures that the finished product will be both functional and attractive.

There are a variety of ways to create a prototype, depending on the specific project requirements. For example, low-fidelity prototypes are basic representations of the final product without any detailed functionality, used in early stages to test concepts and gather user feedback. High-fidelity prototypes are more accurate and close to the final product, often used for visual testing.

3D printing is a popular method for rapid prototyping because it offers a wide range of benefits. It improves communication through visual representations, identifies problems with the design process quickly and efficiently, and provides the opportunity for continuous testing to identify user needs. This iterative process saves time and money, while also reducing risk and enhancing the quality of the final product.

While there are many different 3D printing processes, the most commonly used is fused deposition modelling (FDM), found in most non-industrial desktop 3D printers. A spool of thermoplastic filament is melted and deposited onto a surface layer by layer to build the model. FDM is suitable for most applications, although it is best suited to lightweight and durable parts.

Another widely-used technique is stereolithography (SLA), which uses a laser to solidify a 3D printed model-also in a layer-by-layer process-from a vat of liquid resin. SLA is ideal for complex and large scale models, as well as parts with intricate details.

When creating a prototype, it is important to clearly define the desired test objectives from the start. This will help to avoid wasting time and money on unsuitable materials and techniques. Also, it is essential to include stakeholders in the design and testing process. This will enable all parties to identify and address potential issues in the early stages of development, reducing the chances of costly errors in the future.

Customised Parts

A key benefit of 3D printing is the ability to create customised parts. This is particularly useful for industries that rely on stringent performance standards. For example, automotive manufacturers can use 3D printing to create rugged housings for sensitive components that boast resistances to heat and water. 3D printing is also an excellent tool for reducing product costs and inventory by manufacturing spare parts on demand. This reduces lead times and allows manufacturers to work with reduced stock levels while providing customers with prompt service.

The ability to rapidly produce prototypes is also useful for iterating a design before moving into production. This can be much faster than traditional methods that require the creation of new moulds or tooling. As a result, a single design iteration can be tested in a range of applications to ensure that it is fully functional and fit for purpose. This is especially helpful for high-tech products where small improvements can make a big difference to a final product’s functionality, comfort, aesthetics or efficiency.

Consumer goods companies can also leverage 3D printing to offer personalised products. This is a great way to assert a brand’s creativity and individuality, as well as responding to consumers’ needs and desires. For example, some designers have created ‘print-at-home’ garments that allow customers to print and wear bespoke fashion pieces. The ability to produce a customised part for every customer can also help businesses build loyalty and brand trust.

In healthcare, medical professionals can also leverage the power of 3D printing to produce customised implants and prosthetics for their patients. This is a growing area of the industry that uses digital workflows, such as GrabCAD software available from SYS Systems, to convert imagery from CT and MRI scans into precise 3D models. Then, medical professionals can print custom-made implants and surgical guides to fit perfectly into each patient’s unique anatomy.

Aside from accelerating industrial product development, the speed at which 3D printers operate is also crucial for streamlining supply chain processes. This allows manufacturers to quickly respond to market demands, increase production yields and minimise machine downtimes.

Faster Time-to-Market

The speed of 3D printing allows for design changes that might take months with traditional manufacturing to be implemented in a matter of days. This means companies can quickly iterate and perfect their designs to bring products to market faster. This is particularly useful in the automotive industry, where car manufacturers can quickly print spare parts to keep their production lines running as quickly as possible during breakdowns or for a quick replacement when something breaks.

To produce a 3D printed part, a virtual design must first be made using computer-aided design (CAD) software. This creates precise drawings and technical illustrations of the object, much like a blueprint for how to make it. Then, the CAD file is prepared for 3D printing by breaking down the model into many layers. The process is known as slicing, and it prepares the virtual design for printing by taking it apart into hundreds or thousands of thin horizontal layers. Each layer is then printed with a special plastic or metal material. The final product can then be used as intended.

For example, jewellery designers often use 3D printers to print prototypes and to test the fit of a piece. This allows them to experiment with different shapes and aesthetic finishes, sidestepping some of the limitations of conventional jewelry making techniques such as CNC machining or lost-wax casting. This flexibility also lets designers experiment with new and innovative designs that might not be viable with other methods.

Increasingly, industrial goods manufacturers are using 3D printing as an end-use production technology. This is due to the fact that it can produce a large variety of parts without requiring a complex manufacturing setup or expensive injection molds. It also enables them to produce parts on-demand, reducing the need for costly inventories and enabling supply chain agility.

This capability is already being utilized by aerospace and defence industries to print high-value components in-house, reducing time-to-market for new aircraft or weapons systems. It’s important to note, however, that there are still a few hurdles to overcome before this type of manufacturing can become mainstream, such as ensuring that additively produced parts meet stringent industry standards and have the durability required for end-use.

Reduced Waste

3D printing is a highly efficient process, using the exact amount of material needed to create a part. This greatly reduces waste compared to traditional manufacturing techniques, which typically require large amounts of excess material for assembly and support.

The elimination of waste also helps to conserve natural resources and prevent pollution. Many traditional manufacturing processes rely on sourcing materials from long distances and transporting them for on-site processing, resulting in substantial carbon emissions. By eliminating the need for this transportation, 3D printing significantly cuts greenhouse gas emissions.

Additionally, the use of recycled materials in 3D printing can further reduce the impact on the environment. These materials are derived from a variety of sources, including repurposed filaments and scrap plastics from other 3D prints. Using these materials also helps to reduce the demand for new materials, further decreasing waste.

In addition, a variety of advanced software and design algorithms can be used to optimize the use of material in 3D printing. These strategies, known as topology optimization, help to make structures stronger and lighter, reducing overall material consumption while improving durability. This can lead to a reduction in maintenance costs over time, further reducing the environmental impact of the technology.

By enabling businesses to confirm a design before making the investment of creating physical prototypes, 3D printing reduces the risk of errors and wasted materials. This is a significant advantage over traditional manufacturing methods, where errors can be costly and time-consuming to correct.

With the flexibility offered by 3D printing, companies can manufacture products on-demand and only as they are needed. This can significantly reduce the need for inventory storage, which requires costly space and energy. It can also ensure that parts are made only when the product they are designed for is required, removing waste associated with obsolete or surplus inventory.

In addition, on-demand manufacturing can also reduce the need to import materials from overseas, which can result in a decrease in foreign trade and environmental footprint. Finally, the ability to produce parts locally can reduce the need for long-distance transportation and cut fuel usage, further reducing the impact of 3D printing on the environment.